Vitrified Bond Grinding Wheels / Resin Bond Grinding Wheels Internal

Description

Description

Vitrified/Resin Bond Internal Grinding Wheels

This line of internal grinding wheels features diamond or CBN superabrasives with either vitrified (ceramic) or resin bonds, crafted for precision ID grinding of hard materials like tungsten carbide, hardened steel, and ceramics.

Specifications

Specifications

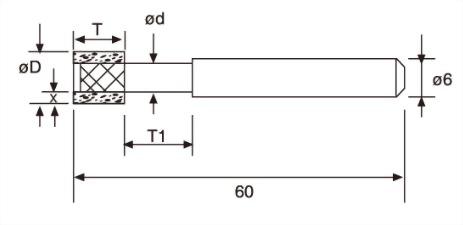

With Shank

Unit: mm

|

Order No. |

D |

T |

X |

d |

T1 |

Bond |

Grit Size |

|

D8 |

8 |

10 |

1.5 |

4.5 |

15 |

Vitrified

Resin

|

D150 B150 |

|

D10 |

10 |

10 |

2 |

6 |

- |

||

|

D12 |

12 |

10 |

3 |

6 |

- |

Concentricity≦0.01mm

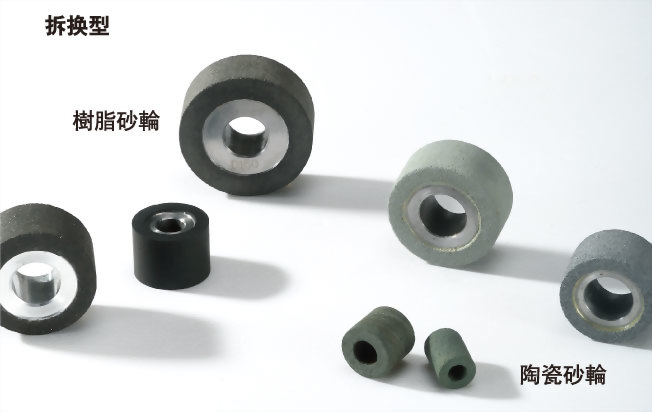

Replaceable Type

Unit: mm

|

Order No. |

D |

T |

X |

H |

Bond |

Grit Size |

|

D16 |

16 |

12 |

2.5 |

6 |

Vitrified

Resin

|

D150 B150 |

|

D20 |

20 |

12 |

2.5 |

10 |

||

|

D25 |

25 |

12 |

4 |

10 |

||

|

D30 |

30 |

12 |

5 |

10 |

After clamping you

will have to dress it until the concentricity is below 0.01mm.

Some dimensions

are make-to-order. Ask before making a purchase. Offer other

specifications according to your drawing or sample.

Features

Features

Vitrified Bond

Advantages:

Excellent self-sharpening: Abrasive grains break off naturally during use, maintaining strong cutting ability.

High thermal resistance: Ideal for high-speed, high-temperature, and long-duration grinding processes.

Superior dimensional stability: Minimal deformation, making it ideal for high-precision applications.

Easily dressable: Compatible with diamond dressers for quick and precise reshaping.

Disadvantages:

Brittle structure: More prone to cracking or damage under impact or side pressure.

Limited in complex shapes: Not suitable for extremely small or intricate forms.

Higher cost: Typically more expensive due to complex manufacturing and materials.

Resin Bond

Advantages:

Good elasticity: Adapts well to uneven surfaces and complex shapes, reducing the risk of chipping.

Smooth grinding action: Produces consistent finishes with minimal vibration.

Lower cost: More affordable and easier to produce in custom shapes and sizes.

Low grinding temperature: Reduces the risk of burning or thermal damage to the workpiece.

Disadvantages:

Faster wear: Shorter service life compared to vitrified wheels; more frequent replacement needed.

Lower heat resistance: Not suitable for continuous or heavy-duty grinding at high speeds.

Reduced dimensional accuracy: Can deform slightly under high pressure or heat.

Abrasive selection

Diamond wheels are best for non-ferrous and tough brittle materials

CBN wheels are tailored for ferrous and hardened steels.

Applications

Applications

Precision machining of carbide, ceramics, hardened steels, and bearing holes

Ideal for high-precision, high-efficiency grinding and polishing of internal bores